Warehouse Equipment

Discover the cutting-edge warehouse equipment that can transform your logistics and operations. Our extensive range includes advanced forklifts, robust shelving solutions, and state-of-the-art conveyor systems, all designed to enhance efficiency, safety, and productivity in your warehouse. Don't let outdated equipment slow you down; upgrade today to experience seamless workflow and improved storage management. Ready to elevate your warehouse operations? Contact us now for a free consultation and take the first step towards a more efficient future!

Warehouse Equipment: Essential Tools for Efficient Operations

Efficient warehouse operations rely heavily on a variety of equipment designed to streamline processes, enhance productivity, and ensure safety. The right warehouse equipment can make a significant difference in the management of inventory, order fulfilment, and overall operational efficiency. Here, we explore the essential categories of warehouse equipment and their specific functions.

1. Material Handling Equipment

Material handling equipment is crucial for moving goods within the warehouse. This category includes:

Forklifts: These are indispensable for lifting and transporting heavy pallets and materials over short distances. There are various types of forklifts, including counterbalance, reach, and pallet jack forklifts, each suited for specific tasks.

Pallet Jacks: Manual and electric pallet jacks are used for moving pallets within the warehouse, ideal for low-intensity lifting tasks.

Conveyors: Conveyors facilitate the movement of goods along a defined path within the warehouse. They can be gravity-driven or powered, helping to reduce manual handling and speed up the sorting and distribution process.

2. Storage Equipment

Effective storage solutions are key to maximising warehouse space and ensuring easy access to inventory. Common storage equipment includes:

Pallet Racks: These racks provide vertical storage space for pallets, helping to organize and utilize warehouse space efficiently. Types of pallet racks include selective, drive-in, and push-back racks.

Shelving Units: For smaller items, shelving units offer a flexible and accessible storage solution. They can be adjustable and are available in various materials like metal, plastic, and wire.

Mezzanines: Mezzanine floors add an extra layer of storage by utilising vertical space. They are often used for storing non-essential items or for creating additional office space within the warehouse.

3. Packaging Equipment

Packaging equipment is essential for preparing goods for shipment. Key equipment in this category includes:

Stretch Wrappers: These machines wrap pallets with stretch film to secure the load during transportation.

Strapping Machines: Used for binding products together or securing them to pallets, strapping machines use plastic or metal straps.

Packing Tables and Workstations: These provide a designated space for packing and preparing orders, often equipped with tools and supplies to improve efficiency.

4. Safety Equipment

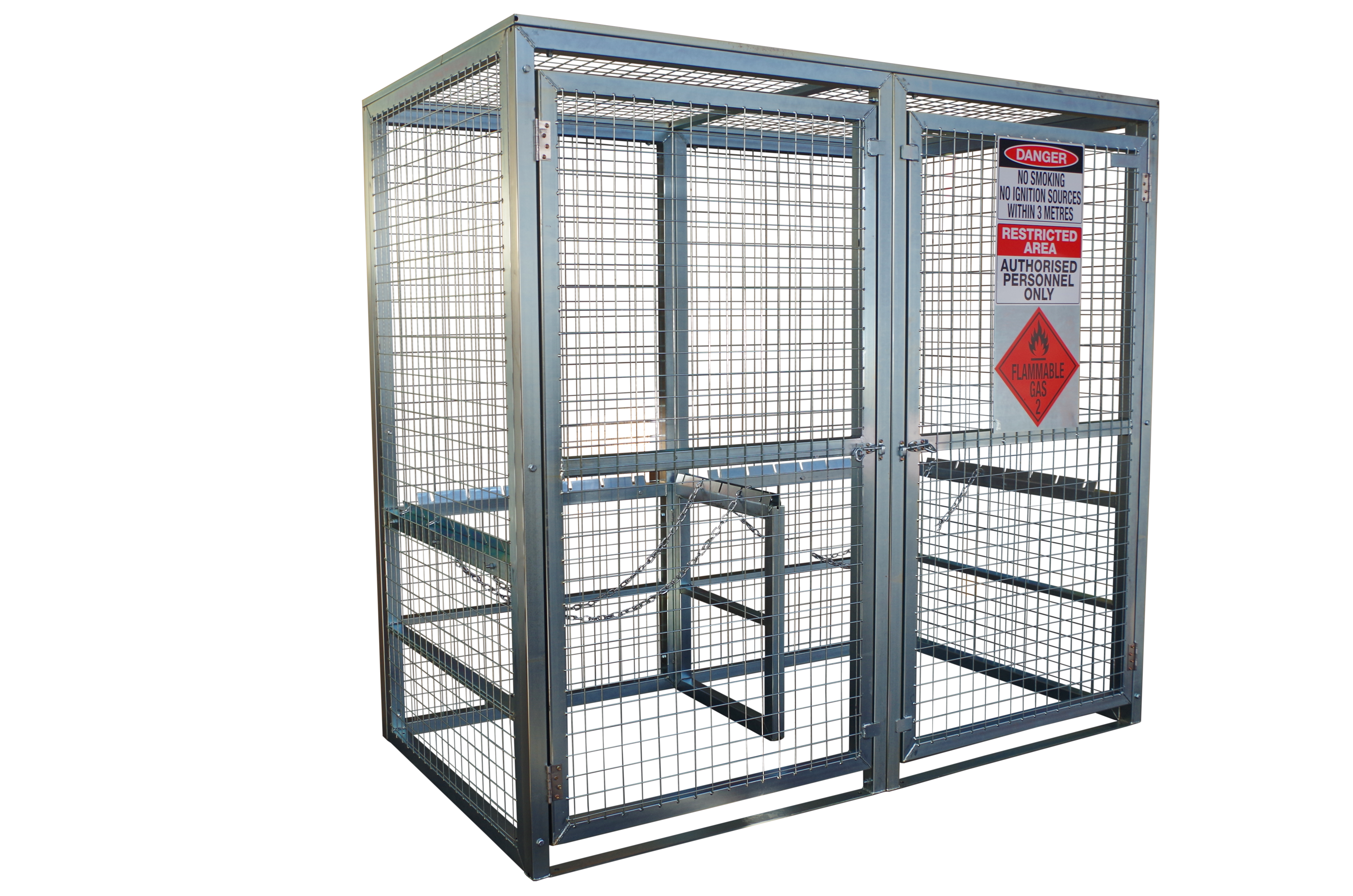

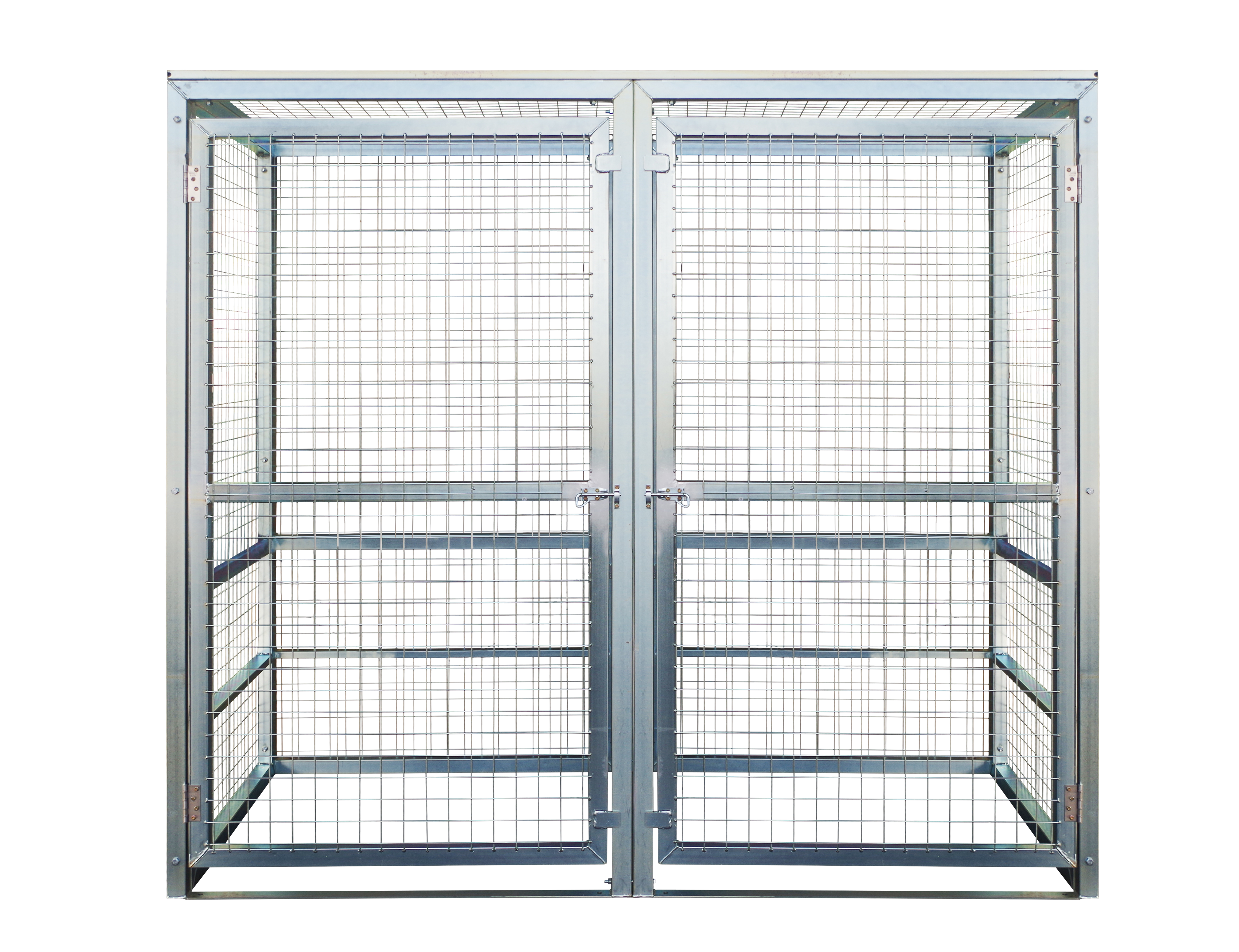

Ensuring safety within the warehouse is paramount. Safety equipment includes:

Guardrails and Safety Barriers: These protect workers from hazardous areas and prevent accidental collisions with equipment.

Safety Nets and Fall Protection: Essential for preventing injuries from falls, especially in areas with elevated storage.

Personal Protective Equipment (PPE): Items like gloves, helmets, high-visibility vests, and safety shoes are necessary to protect workers from various risks.

5. Automated Systems

Automation is increasingly becoming a part of modern warehouse operations. Automated systems include:

Automated Guided Vehicles (AGVs): These are robotic vehicles used for transporting materials around the warehouse without human intervention.

Automated Storage and Retrieval Systems (AS/RS): These systems automatically place and retrieve items from storage locations, increasing accuracy and reducing labour costs.

Warehouse Management Systems (WMS): Software that helps manage inventory, track shipments, and optimise warehouse operations.

Conclusion

Investing in the right warehouse equipment is crucial for improving efficiency, safety, and productivity. From material handling to storage solutions, packaging, safety gear, and automated systems, each category of equipment plays a vital role in the seamless operation of a warehouse. By understanding and implementing the appropriate tools, warehouse managers can significantly enhance their operational capabilities and maintain a competitive edge in the logistics industry.